An industrial manipulator is a machine with a rigid steel manipulator arm that allow complex pneumatic tilts and rotations — even when the product being moved is handled outside it’s barycenter.

An operator leads the manipulator, allowing for easy and precise movement of the manipulator to lift, lower and otherwise transport a Manu fact.

Industrial manipulators are frequently used when:

A Manufact is too heavy for a person to move manually

A Manufact must be moved to a location that is not easily or quickly accessible for a person to reach, like a very tall shelf

When a worker will be put at risk for injury if they move a product manually

When a person will quickly fatigue from moving products manually

A high volume of Manu fact must be moved in a timely fashion

The handiness for the manipulator to move products outside of its barycenter becomes more appreciated as you start working with heavier loads or Manu facts that are not regular- shaped, as other types of machines (including balancers with cables) are not so efficient if not with light or standard shaped products.

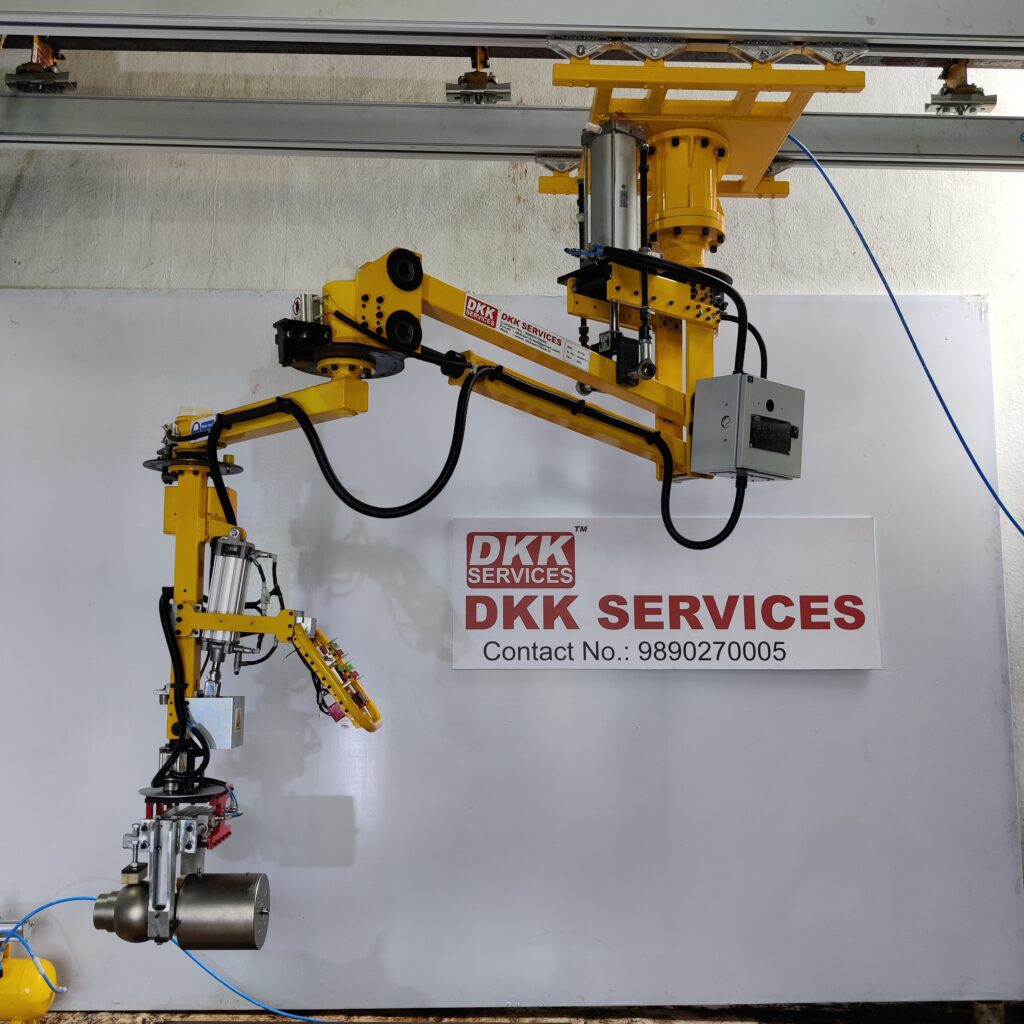

Engine block Handling Zero Gravity Manipulator

Engine Block Manipulator